HMC Holder Manufacturers in Pune-HMC Holders in Pune

HMC Holders Manufacturers, Suppliers, Dealers, Stockist in Pune

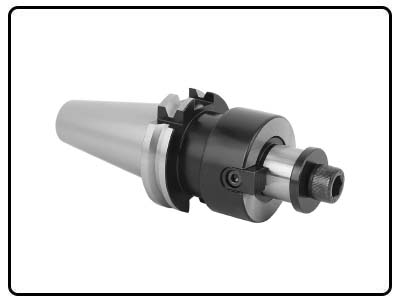

Nandini Enterprises is one of the leading HMC Holders Manufacturers, Suppliers, Dealers, Stockist in Pune. Nandini Enterprises are a leading company in the field of supplying and manufacturing the HMC holders. The HMC Holders Manufacturers in Pune have the best team of experts and the latest designs for the holders. Horizontal Machining Center (HMC) holders are essential elements in advanced manufacturing techniques, designed to safely hold cutting tools and ensure excellent accuracy and stability during machining processes. These holders are made specifically for HMCs, which have benefits including improved chip evacuation and the ability to do demanding cutting tasks. There are many varieties of HMC holders available, such as shell mill holders, end mill holders, and collet chucks, each designed to meet certain tooling needs.

The design of HMC holders highlights robust holding mechanisms and minimal runout, which improves the precision and quality of machined parts. They are made from high-quality materials to withstand the rigors of high-speed and high-torque tasks, ensuring long service life and consistent performance. HMC holders are essential in applications including heavy machinery manufacture, automotive, and aerospace because they offer the stability and precision needed to achieve tight tolerances and excellent surface finishes.

Features of HMC Holders:

- Robust Clamping Mechanisms: HMC holders are filled with robust clamping mechanisms designed to safely hold cutting tools during high-torque and high-speed operations. The precision and caliber of the components that are machined are enhanced by the safe clamping, which is necessary to keep the tool stable and reduce tool deflection.

- Minimal Runout: The precision engineering of holders assures minimal runout, which is important for achieving tight tolerances and superior finishes on the surfaces. These HMC holders enhance overall machining precision and lower the risk of tool wear by preserving concentricity between the tool and the spindle.

- High-Quality Materials: Produced from high-quality materials such as tough steel and specialized alloys, HMC holders are designed to withstand the demanding conditions of heavy-duty machining. Long service life and reliable performance are ensured by this durability, even in the face of constant usage and severe operational stress.

- Versatility: HMC holders are available in a variety of types, such as collet chucks, end mill holders, and shell mill holders. Because of their adaptability, they may be used for a variety of machining tasks, from roughing to finishing, with a wide range of cutting tools. Their versatility increases the flexibility of Horizontal Machining Centers and makes them appropriate for a wide range of production activities.

- Enhanced Chip Evacuation: The design of HMC holders frequently includes features that enhance chip evacuation, a critical aspect of maintaining machining efficiency and tool life. By reducing the possibility of clogging and overheating the tool, efficient chip removal makes cutting operations easier and prolongs the life of the tool and its holder.

- Quick Tool Changes: Many HMC holders are designed to allow quick and efficient tool changes, reducing downtime and improving machine uptime. This feature is especially beneficial in high-volume production environments where reducing setup times is crucial for maintaining high productivity levels.

Benefits of HMC Holders:

- Enhanced Precision: HMC holders ensure little runout and precise tool positioning, which is critical for achieving tight tolerances and high-quality surface finishes. High precision industries like aerospace and automotive manufacturing depend on precision because it produces consistent part dimensions and improved product quality.

- Improved Stability: The robust design of HMC holders provides excellent stability, reducing tool deflection and vibrations during machining operations. This stability improves overall process reliability by improving the quality of the machined parts and extending the life of the machine spindle and cutting tools.

- Increased Productivity: With features that facilitate quick and efficient tool changes, HMC holders significantly reduce downtime and increase machine uptime. This increase in productivity allows for faster turnaround times and increased throughput, which is very helpful in high-volume manufacturing operations.

- Versatility in Applications: HMC holders serve a wide range of cutting tools in Pune, from end mills and drills to reamers and taps. Because of its adaptability, producers can use a single setup for numerous machining operations, which increases the flexibility and efficiency of horizontal machining centers.

- Durability and Longevity: HMC holders are manufactured of strong, long-lasting materials and have been designed to survive the demanding conditions of heavy-duty machining processes. Because of their lengthy lifespan, there is less need for regular replacements, which lowers operating expenses and ensures steady performance over time.

- Effective Chip Evacuation: Chip evacuation is a crucial aspect of HMC holder design, as it keeps machining efficiency high and protects against tool clogging. Reducing the chance of overheating, ensuring smoother operations, and extending tool life are all benefits of effective chip removal.

Application of HMC Holders:

- Automotive Industry: Used for machining engine elements, transmission parts, and other high-precision automotive parts, ensuring tight tolerances and superior surface finishes.

- Aerospace Industry: Essential for manufacturing complex components such as turbine blades, aircraft frames, and landing gear parts, where high precision and reliability are paramount.

- Heavy Machinery: Because the holders can withstand high-torque and high-speed operations, they are perfect for creating massive, heavy-duty components like gears, shafts, and housings.

- Mold & Die Making: Utilizing the stability and low runout offered by HMC holders, this process produces molds and dies that need precise dimensions and complex details.

- Medical Device Manufacturing: Critical to producing precision medical components, such as implants and surgical instruments, where high precision and superior surface finish are critical.

HMC holders are essential components in the realm of advanced machining, offering unmatched benefits in terms of precision, stability, versatility, and efficiency. Long-lasting performance and dependability are ensured by their sturdy design and excellent production, even in the most difficult situations. HMC holders make an important contribution to the manufacture of high-quality components in a variety of industries, including as automotive, aerospace, heavy machinery, mold and die making, and medical device manufacturing, by aiding accurate tool positioning, reducing runout, and extending tool life. They are essential for simplifying production lines, reducing expenses, and producing better machining results because of their adaptability and efficiency when it comes to Horizontal Machining Centers.

The design of HMC holders focuses attention on robust clamping mechanisms and minimal runout, enhancing the accuracy and quality of machined parts. Long service life and dependable performance are ensured by the high-quality materials used in their construction, which can endure the demands of high-speed and high-torque operations. HMC holders are essential in sectors including heavy machinery manufacture, automotive, and aerospace because they offer the stability and precision needed to achieve tight tolerances and excellent surface finishes.Nandini Enterprises is trusted among HMC Holders Manufacturers, Suppliers, Dealers, Stockist in Pune. We request our customers to get in touch with us over a call. Our team of experts is available to answer any questions.